What are the key steps in the customization process of color printed composite bags?

Release Time : 2025-06-18

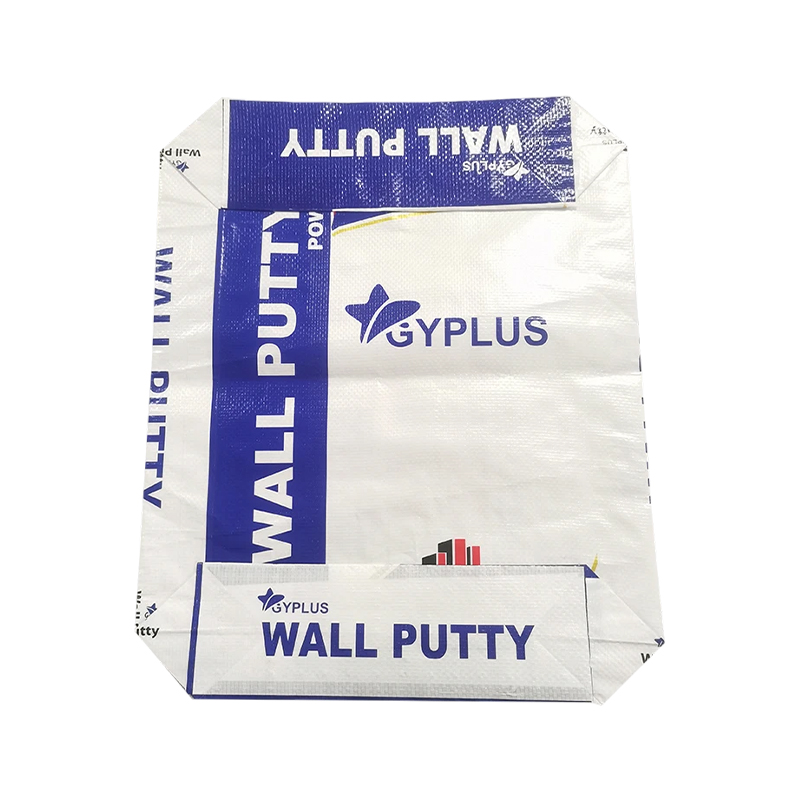

In the modern commodity circulation system, packaging is not only an important means of protecting products, but also a key link in conveying brand image and enhancing market competitiveness. With the increasing requirements of various industries for packaging functionality and aesthetics, customizing various color printed composite bags has become the preferred packaging solution for many companies. This type of packaging bag is widely used in agriculture, chemical industry, food, medicine and other fields, especially for the storage and transportation of fertilizers, feed, corn seeds, grain, woven bags and other products.

Ordinary composite bags are functional packaging bags made of two or more different materials through a composite process. Common material combinations include PE, PP, PET, AL and CPP, each of which has different physical and chemical properties. Through reasonable matching, multiple functions such as high strength, durability, moisture resistance, oxygen barrier, airtightness, and UV resistance can be achieved, thereby effectively extending the shelf life of the product and ensuring transportation safety.

Taking the application in the agricultural field as an example, fertilizer and feed packaging usually need to have good moisture resistance and load-bearing capacity to prevent moisture agglomeration or loss of nutrients during storage; while corn seed and grain packaging bags pay more attention to air tightness and pest resistance to ensure that seeds or grains are not contaminated or deteriorated during transportation and storage. The use of composite bags can not only meet these basic functions, but also enhance brand recognition and market appeal by printing exquisite patterns, corporate logos and product information.

In addition, color printed composite bags also support customized services according to pictures. Users can provide design drafts or samples according to their own needs, and the manufacturer will produce samples. This personalized customization model not only improves the professionalism and pertinence of packaging, but also provides strong support for enterprises to create exclusive brand images. For example, in the food industry, composite bags can be used for vacuum or nitrogen-filled packaging of products such as tea, nuts, and condiments, which can not only maintain flavor but also increase shelf life; in the chemical and pharmaceutical fields, composite bags can be used as safe packaging for materials such as powders, granules, and liquids to meet the special requirements of different industries.

From the production process point of view, the production process of color printed composite bag includes printing, compounding, slitting, bag making and other links. Among them, color printing technology is the key step to determine the appearance quality of packaging. The use of multi-color gravure printing or flexographic printing technology can achieve high-definition, full-color, fine-text printing effects. At the same time, in order to enhance the sealing and durability of the bag, functional structures such as zipper closure, self-supporting bottom, handle, and breathable valve can be added according to customer requirements to further enhance the convenience of use.

As the concept of environmental protection is deeply rooted in the hearts of the people, more and more companies are beginning to pay attention to the development direction of green packaging. Some color printed composite bags have been printed with degradable materials or environmentally friendly inks to reduce the impact on the environment. This is not only in line with the national policy orientation of sustainable development, but also adds a lot to the social responsibility image of the company.

Customized color printed composite bags have become an important choice for packaging upgrades in all walks of life with their excellent physical properties, flexible design space and wide range of applications. Whether it is used for the transportation of agricultural production materials or for the packaging of food, medicine, and electronic products, it can provide reliable product protection and excellent visual presentation, helping companies stand out in the fierce market competition.

Ordinary composite bags are functional packaging bags made of two or more different materials through a composite process. Common material combinations include PE, PP, PET, AL and CPP, each of which has different physical and chemical properties. Through reasonable matching, multiple functions such as high strength, durability, moisture resistance, oxygen barrier, airtightness, and UV resistance can be achieved, thereby effectively extending the shelf life of the product and ensuring transportation safety.

Taking the application in the agricultural field as an example, fertilizer and feed packaging usually need to have good moisture resistance and load-bearing capacity to prevent moisture agglomeration or loss of nutrients during storage; while corn seed and grain packaging bags pay more attention to air tightness and pest resistance to ensure that seeds or grains are not contaminated or deteriorated during transportation and storage. The use of composite bags can not only meet these basic functions, but also enhance brand recognition and market appeal by printing exquisite patterns, corporate logos and product information.

In addition, color printed composite bags also support customized services according to pictures. Users can provide design drafts or samples according to their own needs, and the manufacturer will produce samples. This personalized customization model not only improves the professionalism and pertinence of packaging, but also provides strong support for enterprises to create exclusive brand images. For example, in the food industry, composite bags can be used for vacuum or nitrogen-filled packaging of products such as tea, nuts, and condiments, which can not only maintain flavor but also increase shelf life; in the chemical and pharmaceutical fields, composite bags can be used as safe packaging for materials such as powders, granules, and liquids to meet the special requirements of different industries.

From the production process point of view, the production process of color printed composite bag includes printing, compounding, slitting, bag making and other links. Among them, color printing technology is the key step to determine the appearance quality of packaging. The use of multi-color gravure printing or flexographic printing technology can achieve high-definition, full-color, fine-text printing effects. At the same time, in order to enhance the sealing and durability of the bag, functional structures such as zipper closure, self-supporting bottom, handle, and breathable valve can be added according to customer requirements to further enhance the convenience of use.

As the concept of environmental protection is deeply rooted in the hearts of the people, more and more companies are beginning to pay attention to the development direction of green packaging. Some color printed composite bags have been printed with degradable materials or environmentally friendly inks to reduce the impact on the environment. This is not only in line with the national policy orientation of sustainable development, but also adds a lot to the social responsibility image of the company.

Customized color printed composite bags have become an important choice for packaging upgrades in all walks of life with their excellent physical properties, flexible design space and wide range of applications. Whether it is used for the transportation of agricultural production materials or for the packaging of food, medicine, and electronic products, it can provide reliable product protection and excellent visual presentation, helping companies stand out in the fierce market competition.